Abstract

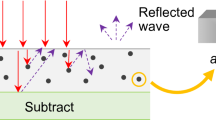

To fabricate a low-reflectance aluminum alloy, we have analyzed the changes in reflectance according to the morphology, components, and composition of the aluminum alloy. We find that the larger the particle size of the powder, the lower is the reflectance. This is attributed to the fact that the larger the particle size, the greater is the amount of light absorbed into the interparticle space in the powder. In addition, the reflectance decreases with increase in the Si and Mg contents, because of the lower reflectance of the strengthening phase formed in the alloy as compared to that of aluminum. In contrast, lanthanide addition causes an increase in the reflectance, which is attributed to an increase in the electrical conductivity of the alloy.

Similar content being viewed by others

References

J.R. Davis, Alloying: Understanding the Basics (ASM International, Russell Township, 1993), pp. 351–416

W.D. Callister, J. Rethwisch, Materials Science and Engineering: An Introduction, 7th edn. (Wiley, New York, 2007), pp. 5–7

J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler, T.M. Pollock, Nature 549, 365 (2017)

D. Manfredi, F. Calignano, M. Krishnan, R. Canali, E.P. Ambrosio, S. Biamino, D. Ugues, M. Pavese, P. Fino, Additive Manufacturing of Al Alloys and Aluminium Matrix Composites (AMCs) (INTECH Inc, London, 2014), pp. 3–7

M.N.E. Efzan, H.J. Kong, C.K. Kok, Adv. Mater. Res. 845, 355 (2014)

C.H. Caceres, C.J. Davidson, Q.G. Wang, J.R. Griffiths, Q.G. Wang, Metall. Mater. Trans. A 30, 2611 (1999)

H.R. Ammar, C. Moreau, A.M. Samuel, F.H. Samuel, H.W. Doty, Mater. Sci. Eng., A 489, 426 (2008)

H. Zandbergen, S. Andersen, J. Jansen, Science 277, 1221 (1997)

C. Caceres, C. Davidson, J. Griffiths, Q. Wang, Metall. Mater. Trans. A 30, 2611 (1999)

M. Yıldırım, D. Özyürek, Mater. Des 51, 767 (2013)

S. Zor, M. Zeren, H. Ozkazanc, E. Karakulak, Anti-Corros. Methods Mater. 57, 185 (2010)

F. Grosselle, G. Timelli, F. Bonollo, Mater. Sci. Eng., A 527, 3536 (2010)

L.Y. Wei, G.L. Dunlop, J. Alloys Compd. 232, 264 (1996)

M. Shamsuzzoha, L.M. Hogan, D.J. Smith, P.A. Deymier, J. Cryst. Growth 112, 635 (1991)

N.D. Mermin, N.W. Ashcroft, Solid State Physics (Holt, Rinehart and Winston, New York, 1976), pp. 671–692

M.G. Blaber, M.D. Arnold, M.J. Ford, J. Phys. Chem. C 113, 3041 (2009)

M.H. Mulazimoglu, R.A.L. Drew, J.E. Gruzleski, Metall. Trans. A 20, 383 (1989)

J. Wang, S. Yue, Y. Fautrelle, P.D. Lee, X. Li, Y. Zhong, Z. Ren, Sci. Rep. 6, 24585 (2016)

M.B. Wasu, A.R. Raut, Int. J. Adv. Res. Chem. Sci. 2, 1 (2015)

J.C. Bae, S.S. Kim, M.H. Park, T.G. Ha, H.S. Lee, W.J. Kim, K.W. Jang, T.K. Song, H.J. Kim, J.S. Song, Integr. Ferroelectr. 65, 49 (2004)

Acknowledgements

This work was supported by the Materials and Components Technology Development Program of MOTIE/KEIT [10077396, Development of aluminium spheroidized powder of 10 to 50 size over 320 MPa strength for additive manufacturing].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choi, G.M., Kim, D.G., Im, B. et al. Reflectance Characteristics of Al Alloys Containing Si, Mg, Cu, and Lanthanide (Nd, Sm, Gd) for 3D Printing. Met. Mater. Int. 25, 946–955 (2019). https://doi.org/10.1007/s12540-019-00256-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00256-9