Research department

- Research Fields

- HOME

Research Fields

INSTITUTE FOR ADVANCED ENGINEERING

Development of energy/resource circulation production process technology for high-moisture organic waste resources

• Integrated plant based on hydrothermal carbonization for simultaneous production of biosolid fuel and biogas

→ Solid fuel production energy consumption: 230 Mcal/ton-waste or less

→ Biogas production: 20Nm3/ton-waste or more

- Integrated biogasification technology applying thermal hydrolysis/hydrothermal carbonization of organic waste resources

- Optimized operation technology for EPC and O&M of integrated process for converting organic waste resources to energy

Development of technology for reuse of high-concentration industrial wastewater and recovery of useful resources

• High-efficiency electrode-based non-biodegradable wastewater treatment and metal recovery technology

→ Electrode life: 7 years or longer, current efficiency: 30% improvement

• Nitrogen compound recovery and productization technology from wastewater containing high concentration ammonia

→ Nitrogen recovery efficiency of 95% or higher, power cost reduction of 70% (compared to room temperature degassing)

• Sterilization system for reuse of high-concentration brine in food production processes

Production and utilization of high-specific-surface-area adsorption materials from waste resources and biomass

• Technology for producing carbon-based adsorption materials with a specific surface area of over 2,500 m²/g.

• An integrated plant with the capacity to produce 30 kg/day of carbon-based adsorption materials having a specific surface area over 2,500 m²/g.

• Manufacturing technology for automotive vapor recovery parts using carbon adsorbents with a high specific surface area.

• An energy production plant capable of generating 30 kWe from volatile organic compounds (VOCs).

• Technology for the regeneration of spent activated carbon and the production of high-specific-surface-area activated carbon utilizing desorbed gases.

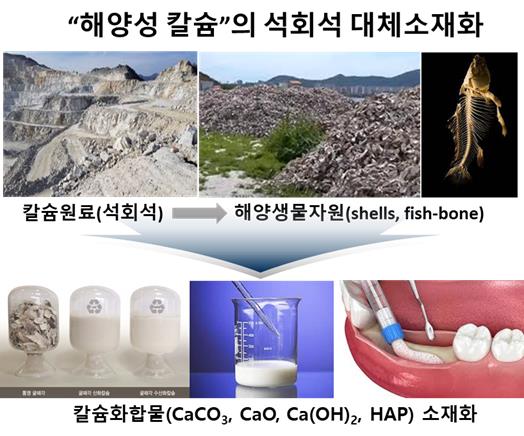

Materialization of Marine Calcium-Based Alternatives to Limestone

• Development of environmental materials (CaCO3, CaO, and Ca(OH)2) utilizing domestically discarded seashells

• Synthesis technology for medical-grade artificial bone materials, specifically the composition control and synthesis of β-TCP/HAP (tricalcium phosphate/hydroxylapatite) based on fish bone-derived calcium, exhibiting excellent biocompatibility.