Research department

- Research Fields

- HOME

Research Fields

INSTITUTE FOR ADVANCED ENGINEERING

1) Product technology based on multi-dimension

Product technology based on multi-dimension is a technology that combines system design, CAE analysis, and test evaluation technologies necessary for product development, based on product life cycle activities of system engineering. CAE analysis is performed to virtually verify the function and performance prediction of product development through requirements analysis, and therefore understand product’s reliability and evaluation at the prototype production stage.

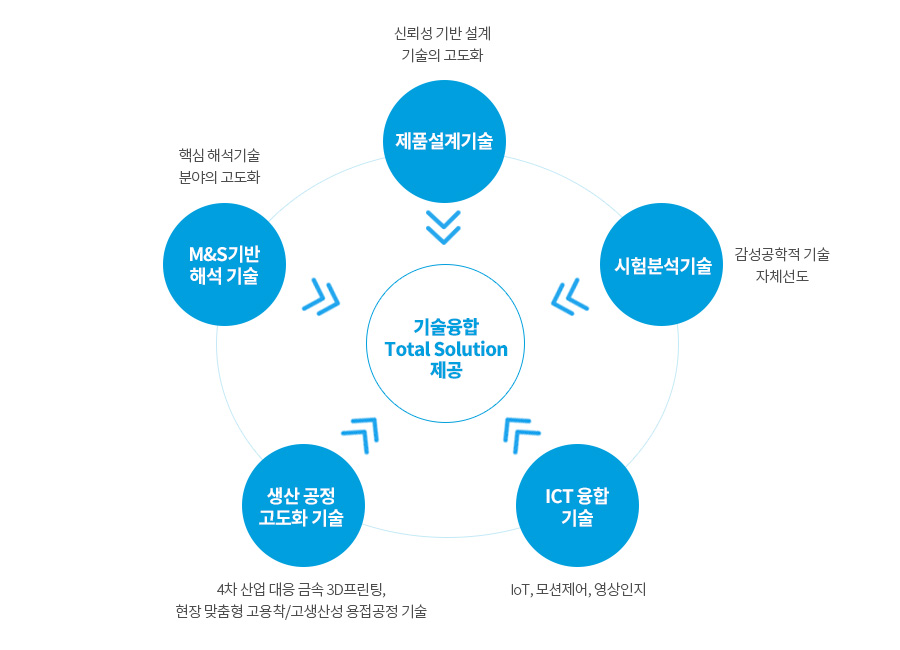

The center focuses on creating practical values by providing total solutions necessary for product development through the convergence of technologies in various fields such as machinery, electricity/electronics, and materials.

Design technologies

- Optimal design technology based on System engineering

- Reverse design technology by 3D scanning

- Ergonomic design technology

- Product design technology using waves

CAE technologies

- Dynamic analysis

- Structural/vibration/ noise/durable analysis

- Thermal/fluid/particle/ electromagnetic analysis

- Injection/extrusion/press molding analysis

Verification technologies

- Vibration/noise/acoustic

- Fine particles (PM2.5/PM10) evaluation technology

- Fatigue/reliability evaluation technology

- Emotional evaluation technology

2) Advanced manufacturing/production processes and SHM solutions

Advanced manufacturing/production processes and SHM (Structure Health Monitoring) advancement technology are essential for advanced part manufacturing in various fields (machinery/aviation/electronics/shipbuilding/marine/plant, etc.) including eco-friendly automobiles and area that requires sound quality of welded structures. They also take an important role in the advancement of root industry and technologies that encompasses overall product development and production.

With these advanced technologies, we are contributing to the revitalization of research and development, starting from materials development to improved product qualities, to create continuous values from intelligent cutting-edge manufacturing/production processes, and therefore, ensuring the product’s structural safety.

Intelligent Welding/Bonding Process and AM Technology

- Environmentally friendly parts welding, bonding and fastening technology

- Ultra-precise laser welding technology

- Quality judgment technology through automation and monitoring of welding processes

- Customized 3D printing and AM technology

- SHM and non-destructive inspection technology

- Design of ultrasonic system for defect detection of welding/junction and AI application analysis technology

- Real-time monitoring technology of welding structures and parts (AE applied)

- Development technology of standard materials for non-destructive inspection

Development of Advanced Materials Production Process Technology in Root Industry

- Multifunctional metal base composite material manufacturing process and molding technology

- Development of high functional welding/bonding materials (solder, etc.) Securing the multifunctional function of parts

- Cladding and surface stacking technology of dissimilar metal materials Improving mechanical and physical properties Nonferrous metal alloying technology

- Providing various solutions to production processes in the root industry (automation/ state-of-the-art)

3) AI & ICT based control platform solutions

ICT convergence technology is a critical technology element (CTE) in AI & ICT control platform that allows new added value to be created through convergence within other industries as well as the ICT industry. We are promoting research and development in areas focused on intelligent sensor and video signal processing, artificial intelligence, robot precision control, and IoT platform technology.

IoT-based monitoring and control integrated platform technology

- System Solutions for Network Distributed Real-Time Control

- IoT-based monitoring and control integrated platform technology

- RTOS-based Embedded Controller Design/Development for Distributed Real-Time Processing

- Scalable component-based gateway S/W architecture and framework

- Controller redundancy for Fault Tolerant system configuration

- QoS and CV (Causality Violation) related technologies to enhance data reliability

AI-based eco-friendly-human-machine interface convergence technology

- Multifunctional metal base composite material manufacturing process and molding technology

- Unstructured data analysis and AI-based process control technology

- Production worker workload measurement and adaptive process control technology

- AI-based behavioral pattern analysis and healthcare signal processing technology

- Human cyber physical-based adaptive product inspection automation technology

Ultra-precise platform-based application technology

- Design and manufacture technology of high-speed radar for piezoelectric device-based defense industry

- Development of test and test evaluation technology for performance tests

- Development technology of mobile reflector for disaster safety micro-Michelson spectroscopy

- Development technology of ultra-small/ultra-fine/high-reliability mirror support unit

Image recognition technology

- 2D/3D image high-speed object detection/recognition technology

- Real-time 3D position and posture estimation technology

- Human cognitive technology

Core Components for Future Mobility

- (Convenience & Interface) Steering wheel technologies for enhanced occupant convenience and interface

- (X-by-wire) Electrified chassis modules and platform technologies for future mobility

- (Crash Safety) Safety performance validation using simulation models and virtual testing platforms

- (Lightweight Components) Design and optimization of lightweight body structures

Technologies for Electronics, Defense, and Equipment Systems

- (Electronics) Optimal design of coreless motors for wearable robots

- (Future Mobility) Battery thermal management systems and active noise reduction control technologies

- (Defense) Flow rate prediction for K-9 self-propelled artillery and optimal design of fume extractors and muzzle brakes

- (Advanced Equipment) Design and optimization of energy-efficient extruders

Energy and Environmental Solution Technologies

- (Energy) Design and analysis technologies for alkaline/PEM water electrolysis stacks and core components

- (Energy) M-BOP design and scale-up technologies for water electrolysis systems

- (Environment) Air quality improvement through particle behavior analysis and measurement

- (Environment) Fine dust control and capture validation technologies

Advanced Manufacturing and Production Process Technologies

- (Advanced Manufacturing) Polymer/metal additive manufacturing process technologies

- (Advanced Manufacturing) Development of ultra-precision sensing technologies for advanced production processes

- (Production Processing) Welding, joining, and fastening technologies for lightweight dissimilar materials

- (Production Processing) Automation technologies for inspection of welded, joined, and fastened components

AI-Based Structural Health Assessment and Quality Inspection Technologies

- (SHM) Non-destructive condition monitoring and predictive maintenance technologies

- (AI Convergence) Development of industrial AI-based optical inspection systems

- (AI Convergence) AI-based weld quality prediction and process control technologies

- (Convergence) Integrated control technologies for intelligent sensor-robot systems

Advanced Processing Technologies Based on High-Performance Materials

- (Advanced Processing) Design and manufacturing of functional alloys based on microstructure control

- (Composite Materials) Development of high-conductivity composites for power supply components

- (Advanced Processing) Development of joining material manufacturing processes in response to environmental regulations

- (Advanced Processing) Manufacturing processes for next-generation semiconductor packaging materials and components