Research department

- Research Fields

- HOME

Research Fields

INSTITUTE FOR ADVANCED ENGINEERING

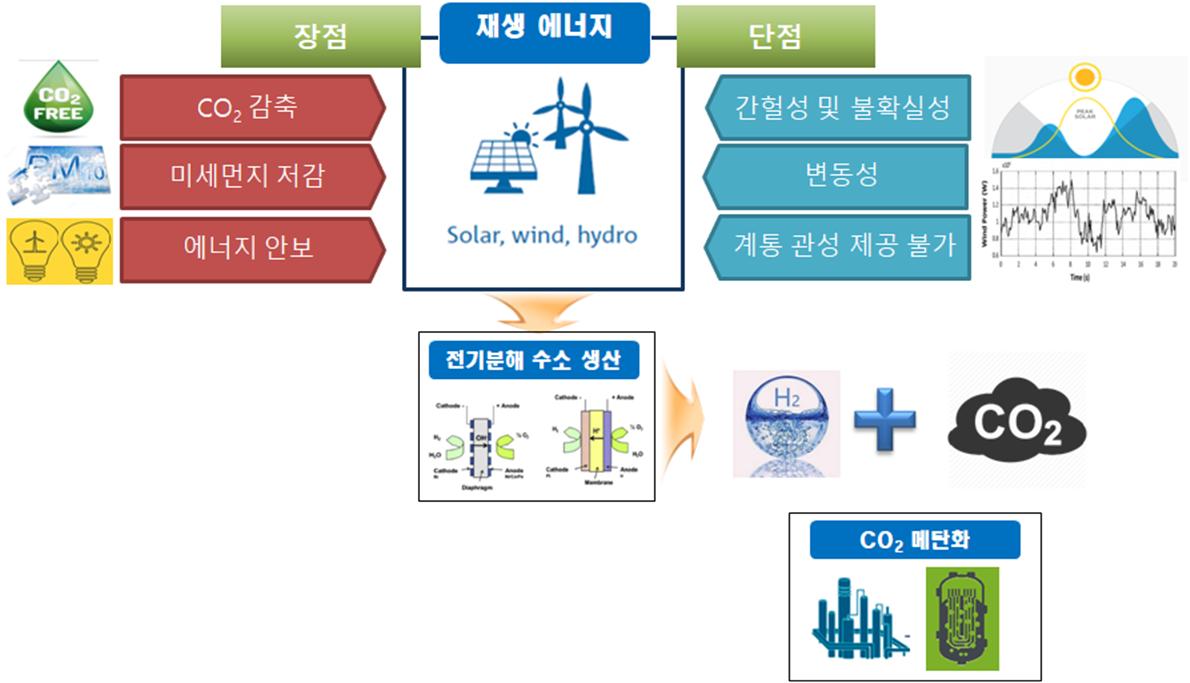

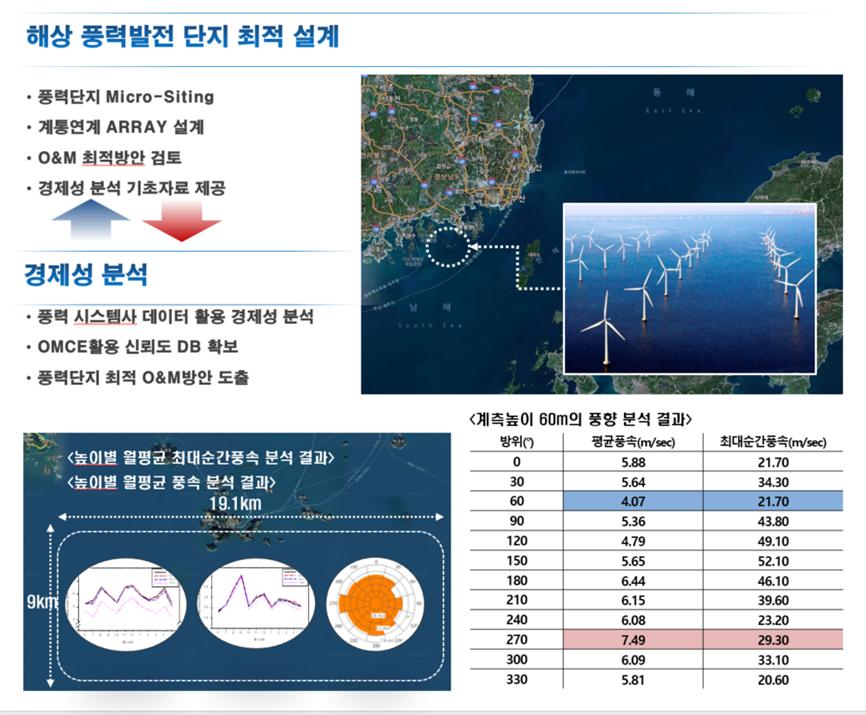

Renewable Energy

R&D on design and analyses for biomass and waste bio-energy system

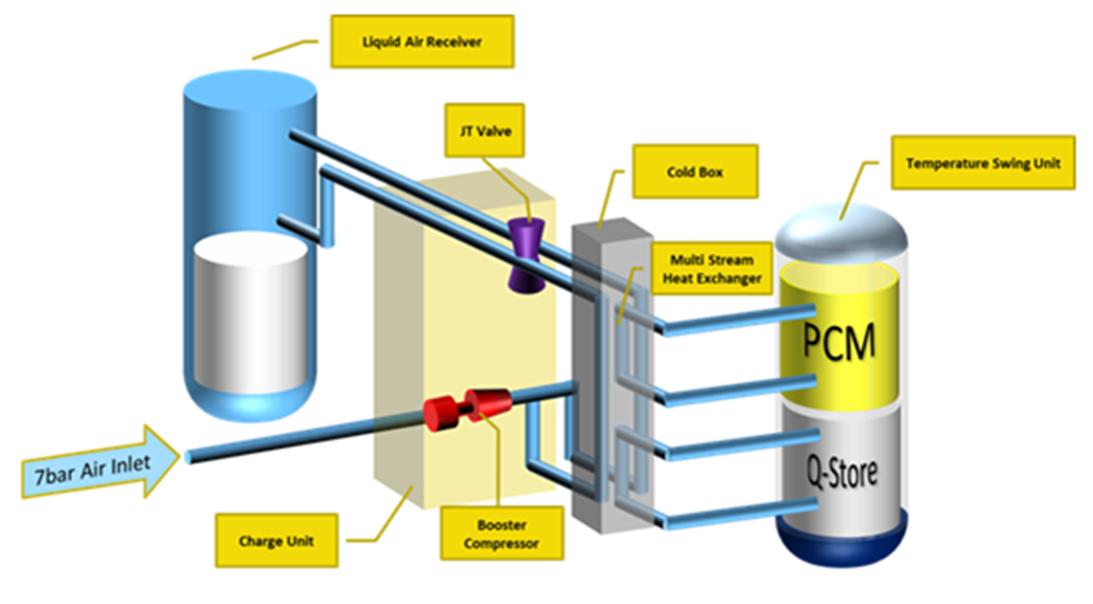

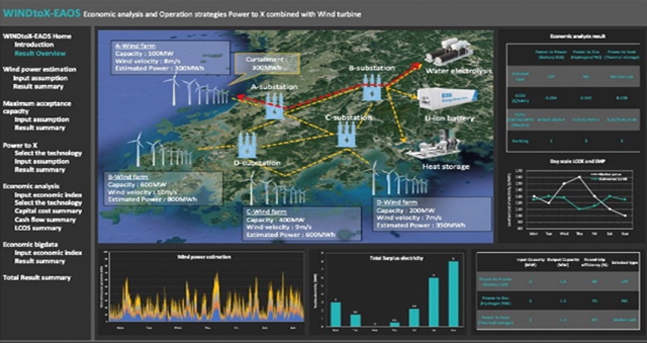

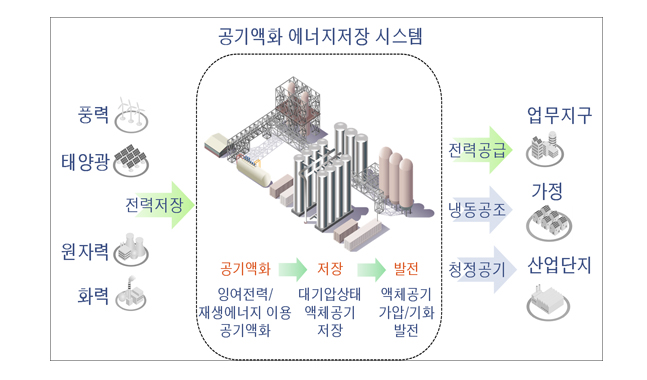

R&D on core technologies in the energy systems, Power to Gas, Liquefied Air Energy Storage, and Compressed Air Energy Storage System

- Biomass torrefaction technology

- Biomass sludge combustion melting technology

- Waste gasification technology

- Biomass tri-generation system

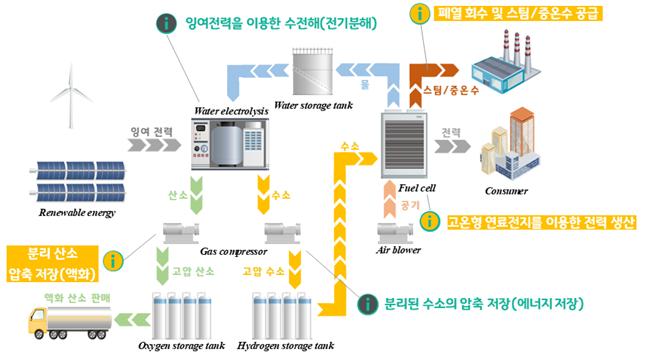

- Power to gas technology

- P2X optimal operation technology

- Liquefied air energy storage technology

- Compressed air energy storage technology

CO2 Capture and Utilization

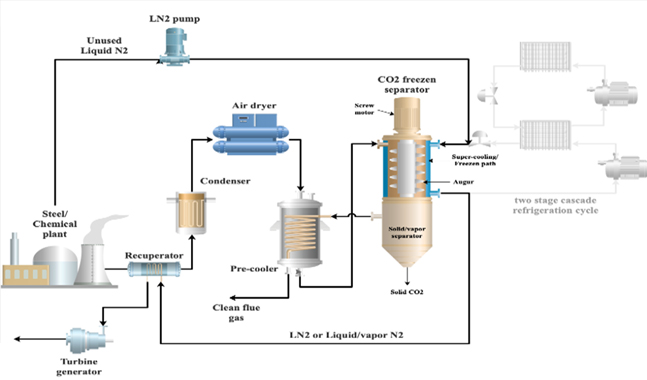

Process analysis and core technology development for capture/utilization of CO2 generated from various emission sources

- Carbon capture & utilization process analysis and feasibility assessment

- CO2 separation and conversion technology

- Cryogenic carbon capture technology

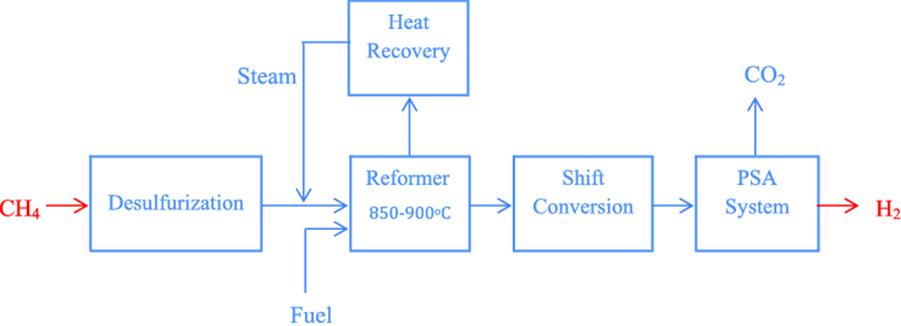

Clean Energy

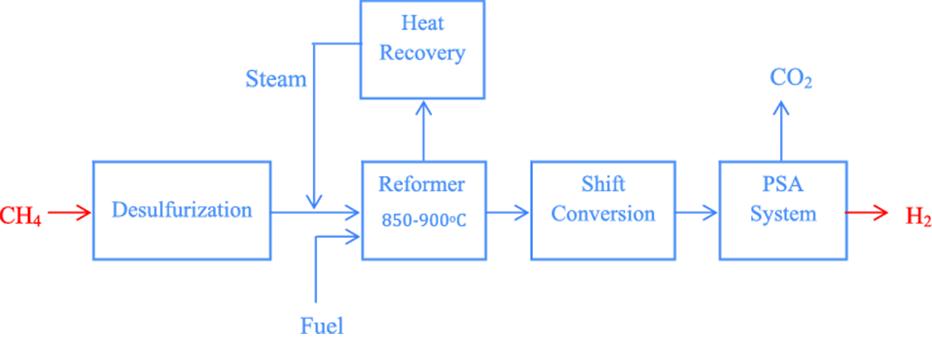

Development of elemental technologies to discover clean energy, including hydrogen production technology based on gasification of low-grade fuel, waste, and hydrocarbon-based fuel, and biological/plasma-based hydrogen production technology

- Biological hydrogen production

- Hydrogen production technology based on waste gasification

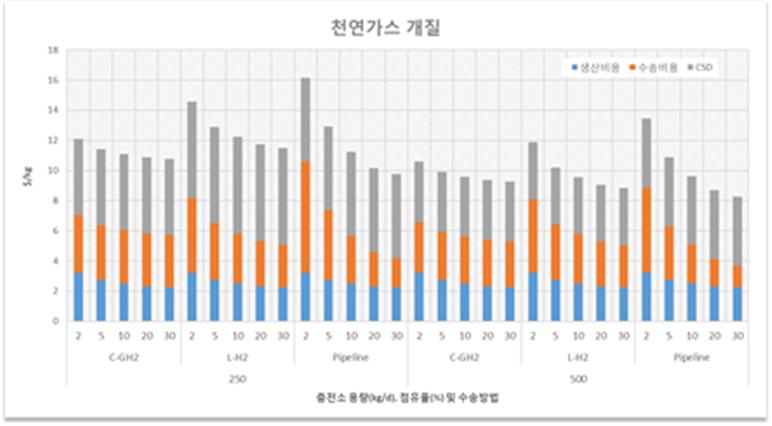

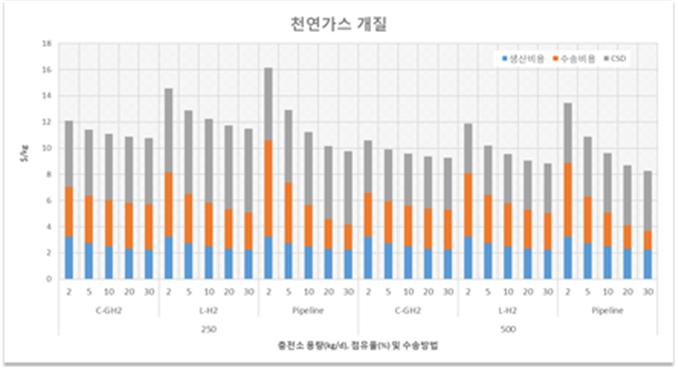

- Hydrogen production process economic/environmental evaluation technology

- Hydrogen station design

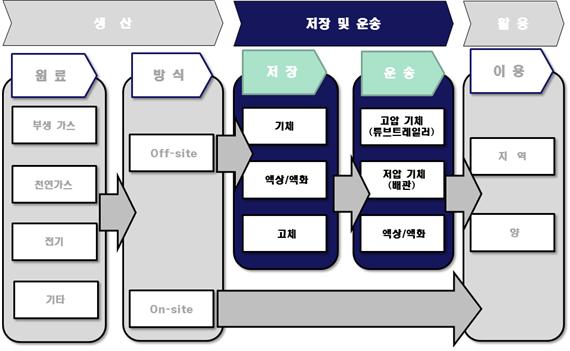

- Hydrogen storage/transportation economic/environmental evaluation technology

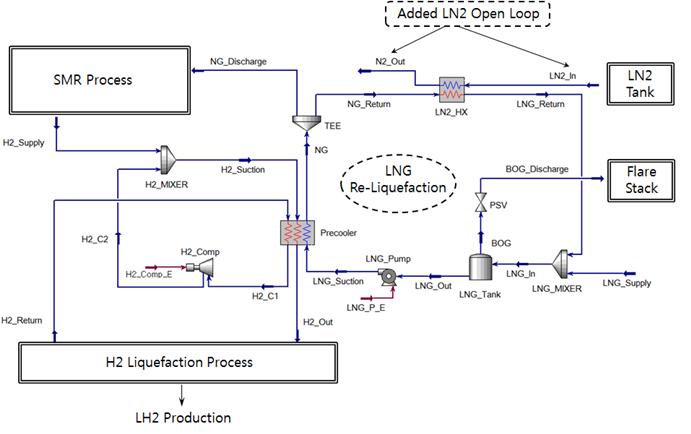

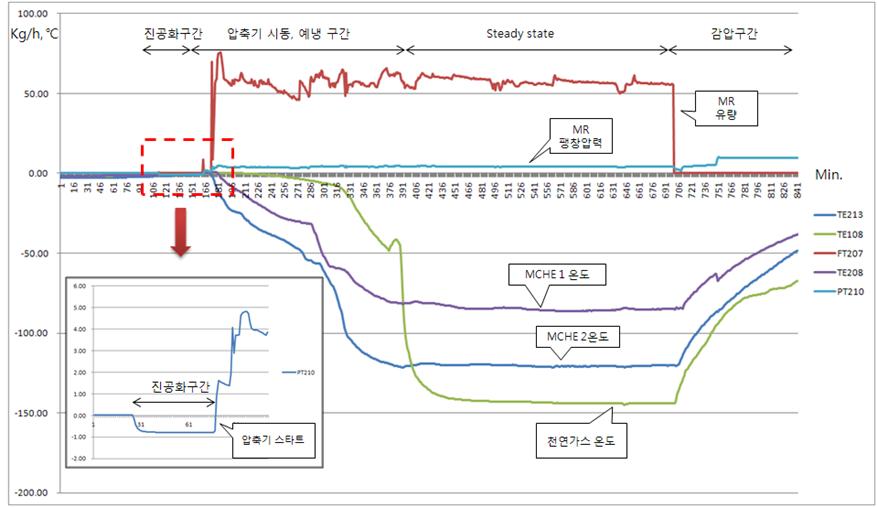

- Hydrogen liquefaction technology

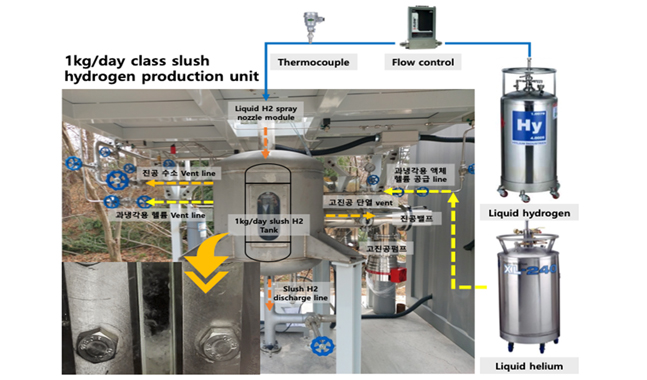

- Slush hydrogen production and zero boil-off technology

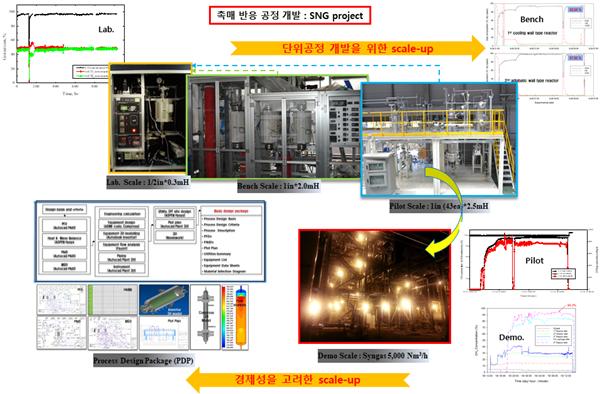

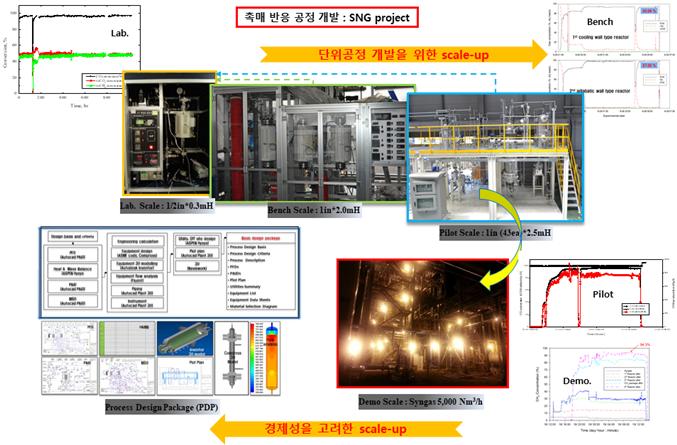

- CO2 methanation technology

- Methanol synthesis technology using synthesis gas

- Fuel cell-battery hybrid system optimal control technology

- SRF oxygen enriched combustion technology

- LNG regasification technology

- Removal of fine particles in oil sands

Energy System

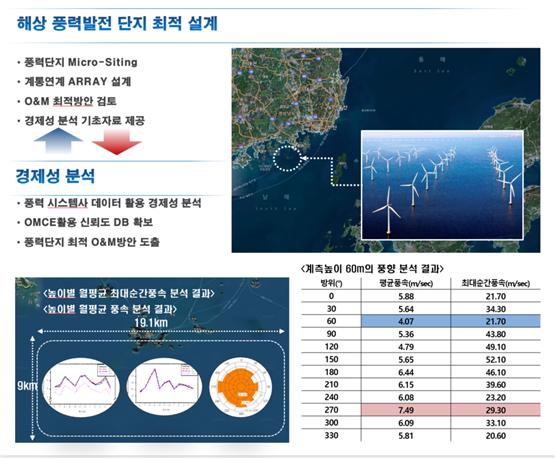

Optimized solutions and energy storage for energy efficient operation·

- FEMS energy optimization solution

- System requirements analysis technology

- PCM thermal storage

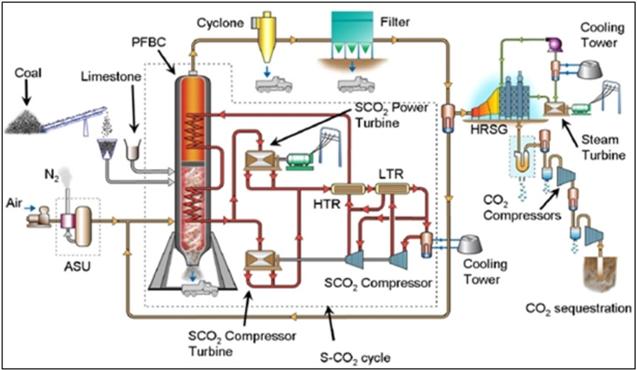

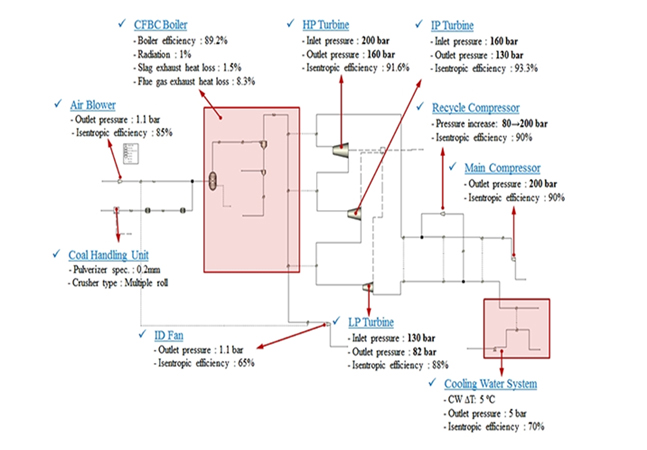

Power Plant

R&D on design and analyses for innovative electric power plants. such as supercritical carbon dioxide power system, new NPP technologies, and so on that can replace traditional power plant system.

- Nuclear reactor exhaust system design technology

- Supercritical carbon dioxide power generation technology

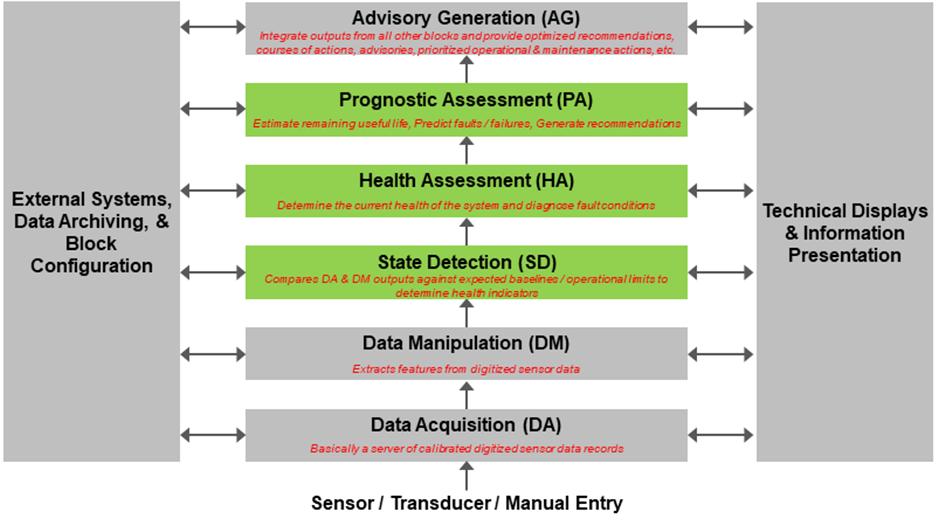

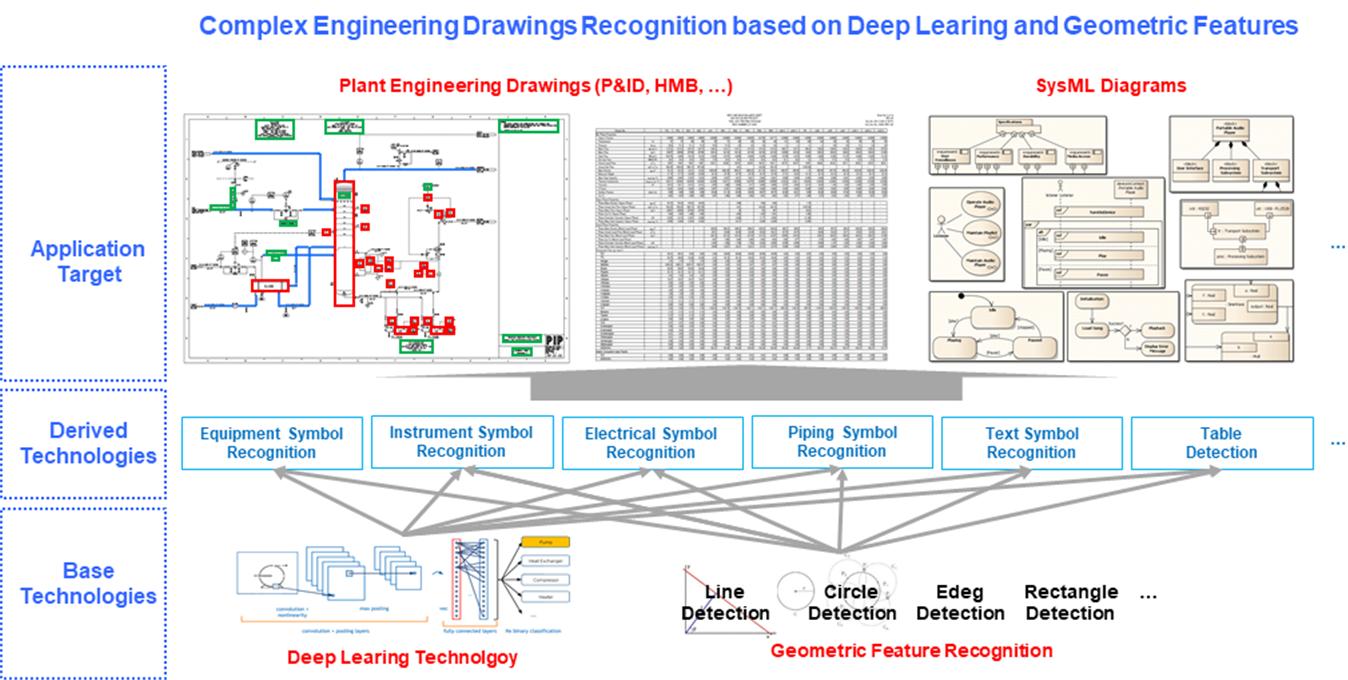

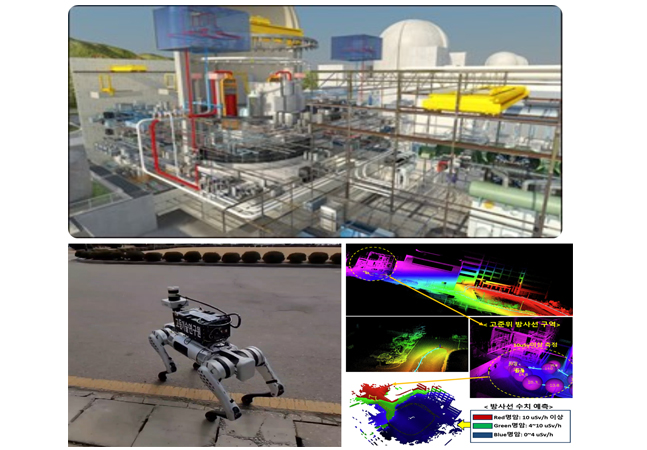

Digital Engineering

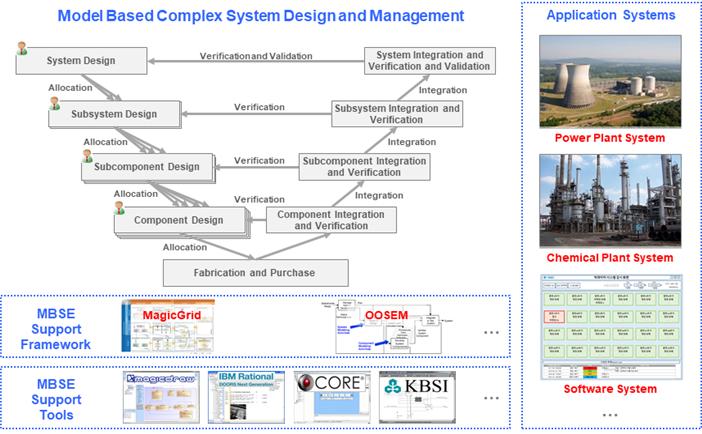

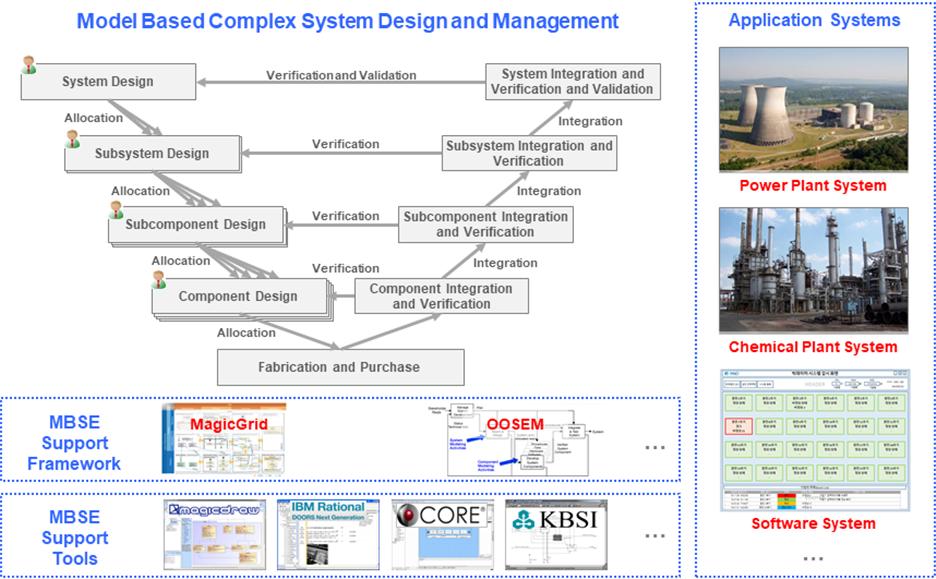

R&D on design, analyses, and modeling technologies in plant industry based on virtual plants combining with advanced digital technologies

- Digital plant engineering and digital twin technology

- Energy demand response and prediction technology

- Recognition and digitalization technology of 3-dimensional configuration

- Application of AI techniques for design information cognition technology

- Health monitoring and diagnosis technologies for nuclear steam supply system.

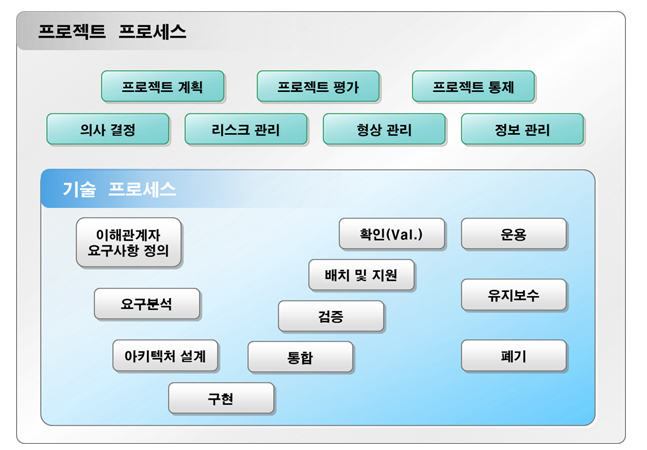

- System modeling based on Sytems Engineering approach.

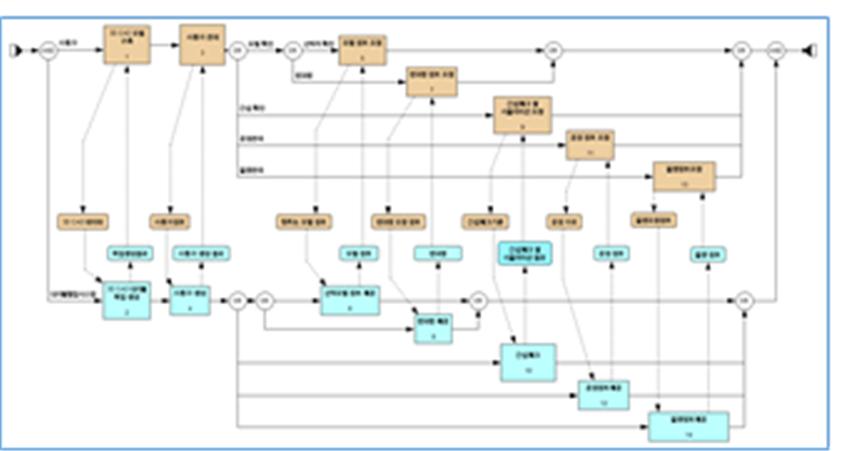

- Technology management and gate review

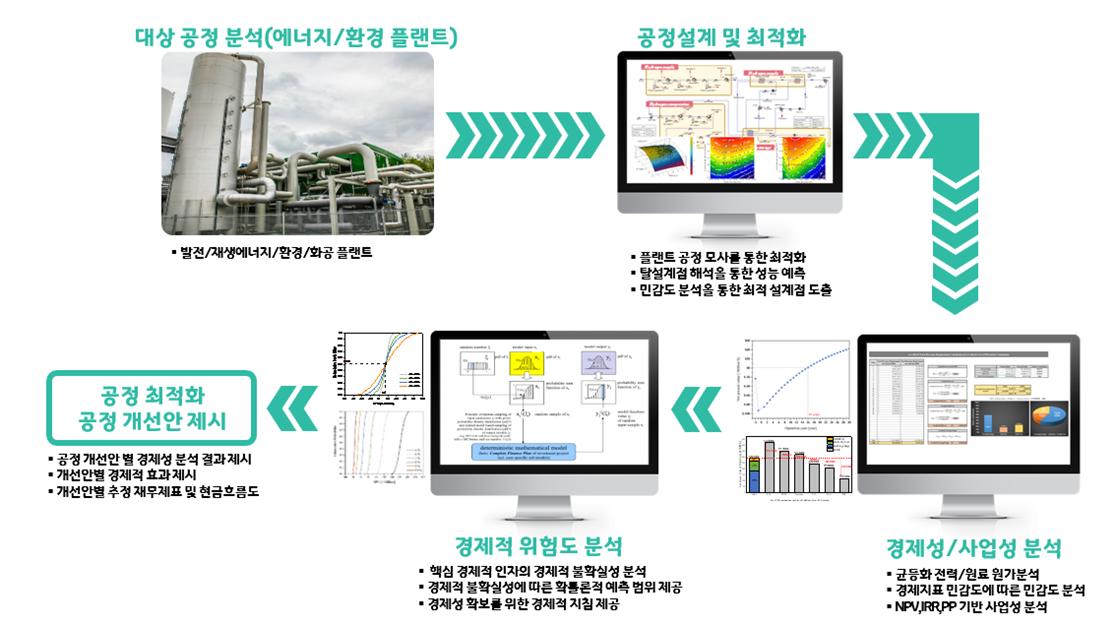

Plant Analysis

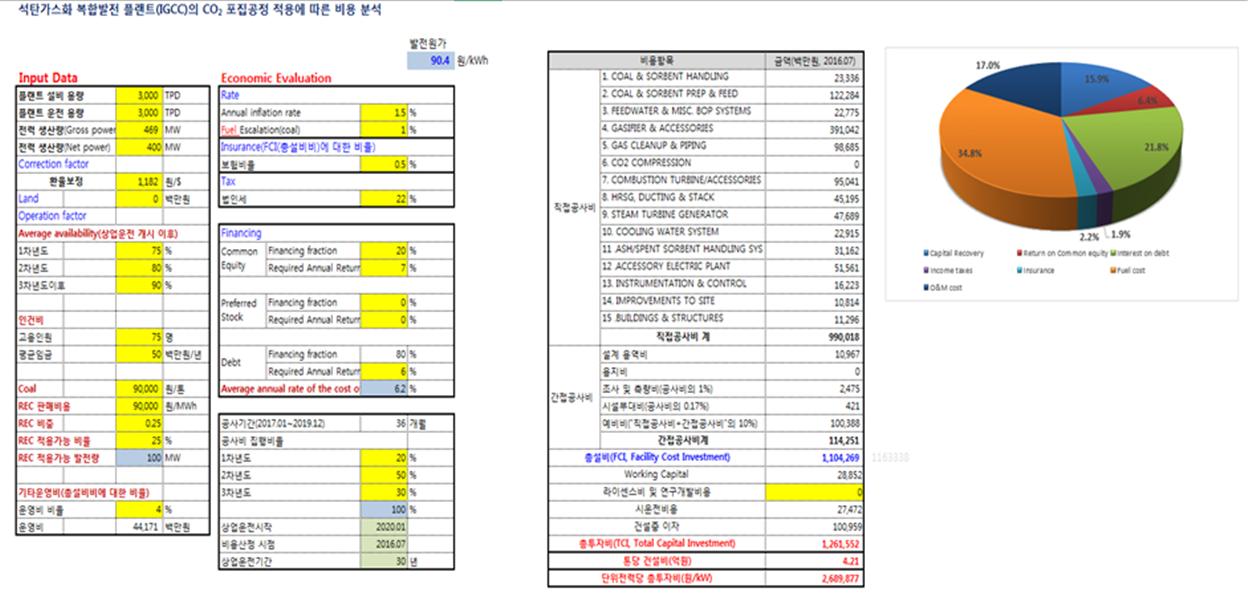

Development of fully life-cycle analysis technology covering technical feasibility, economic feasibility assessment, and risk/availability based on plant process analysis technology

- Plant feasibility assessment technology

- Plant technology/economic feasibility/business evaluation technology

- Plant modularization technology

- Plant risk/availability analysis technology

Life Cycle Assessment (LCA)

Development of a methodology for life cycle assessment of hydrogen technology in the land, infrastructure and transport sector

- Development of a calculation module for life cycle assessment (LCA) of hydrogen technology

- User-centered design and design of calculation modules suitable for the domestic environment

- Establishment of a platform-linked utilization plan

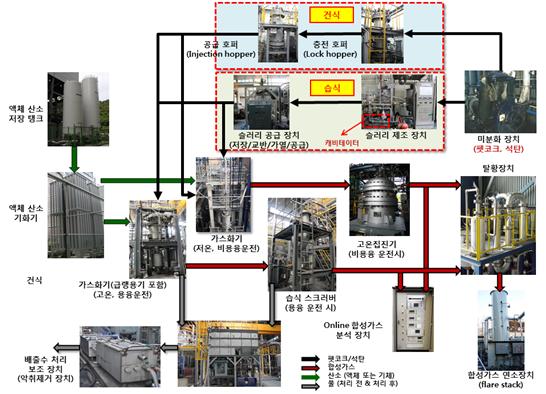

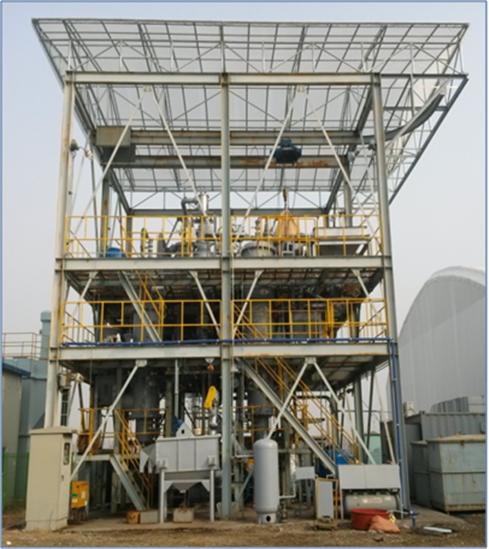

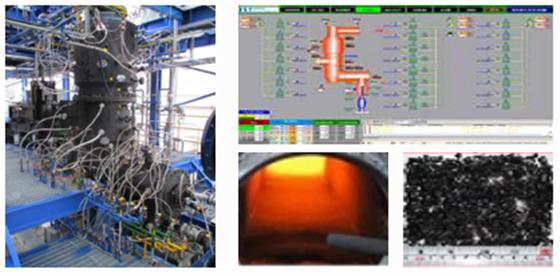

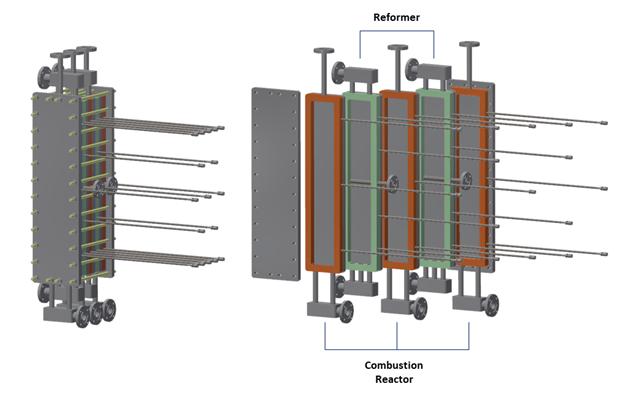

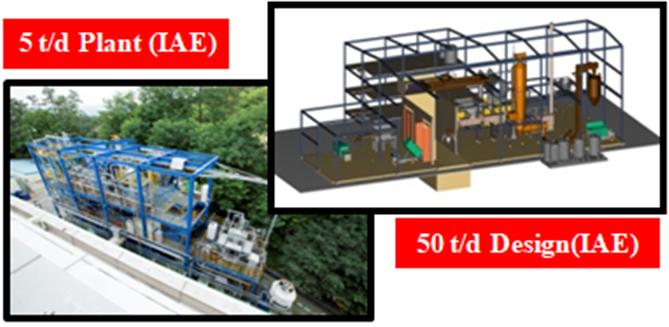

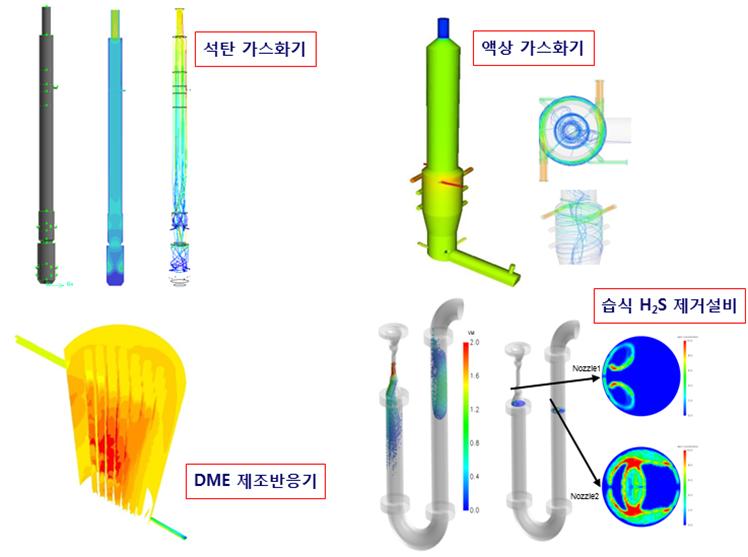

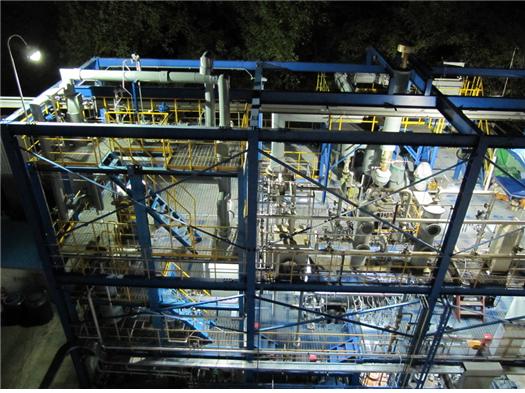

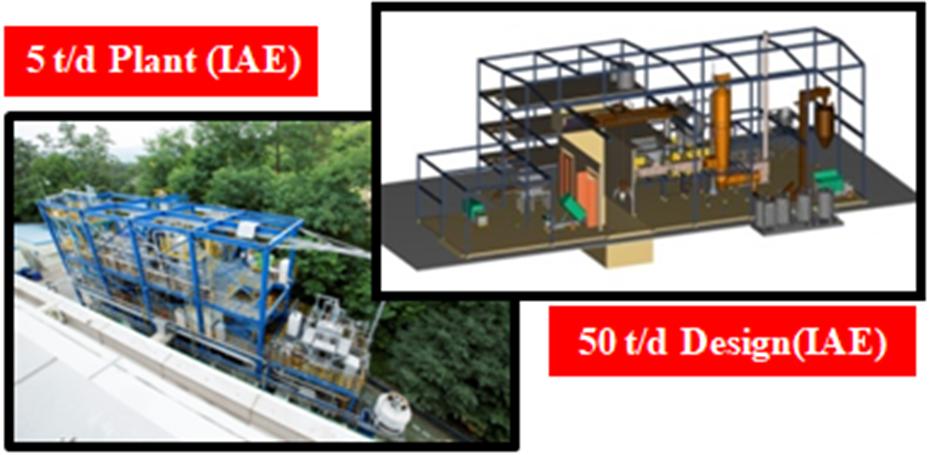

Gasification-based Syngas and Hydrogen Production Plant Technology

Gasification plant technology refers to the process of converting feedstocks such as coal, petroleum coke, and biomass into synthesis gas(syngas) primarily composed of carbon monoxide(CO) and hydrogen(H₂) through high-temperature and high-pressure gasification reactions.

- Syngas and Hydrogen production from various low-grade feedstocks (e.g., coal, petroleum coke)

- Provision of turn-key solutions for the design, construction, and operation of syngas and hydrogen production plants

- Syngas Purification and Utilization Technologies

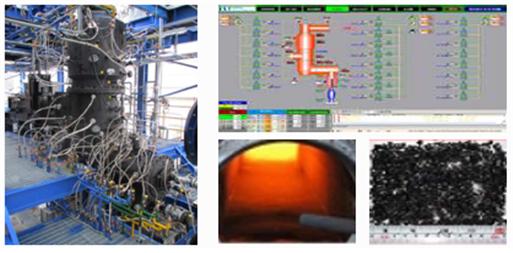

Hydrogen Ultra-Flexible Combustion Technology

A next-generation combustion technology that enables seamless transition from conventional methane-based fuels to 100% hydrogen. This technology allows for variable hydrogen blending ratios ranging from 20% to 100%, enabling flexible response to load demands. It supports a gradual and efficient transition to a hydrogen economy while maintaining compatibility with existing infrastructure.

- Flexible hydrogen co-firing capability ranging from 20% to 100%

- Multi-stage partial premixing for combustion speed control

- Slit flame shape control for flame stabilization and dispersion

- Fully premixed surface combustion for reduction of GHG emissions (NOx, CO₂)

- Flame visualization using spectrally invisible intermediate species (e.g., OH⁻ radicals)

DCSG(Direct Contact Steam Generator)

Combustor technology that supplies steam and combustion gas generated by directly injecting water into a high-temperature combustion environment to the oil sands reservoir

- Optimization technology for composite heat carrier generation

- High temperature/high pressure combustor control technology

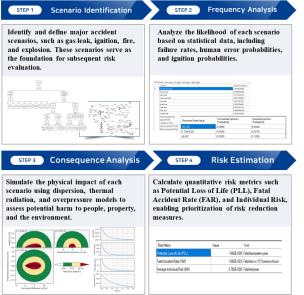

Risk assessment and safety management technology for hydrogen

Hydrogen Risk Assessment and Safety Management Technology focuses on scientifically analyzing potential accident scenarios and consequences in the design and operation of hydrogen infrastructure.

- Development of Hydrogen-Specific Quantitative Risk Assessment Methods

- Design of Integrated Safety Management Systems

- Development of Hydrogen Accident Scenario Analysis and Visualization Tools

- Safety Policy & Standard Proposals to Enhance Public Acceptance of Hydrogen Facilities

VOCs(Volatile organic compounds) treatment and intelligent monitoring technology

Develop intelligent carbon reduction technology to enhance the safety of carbon (volatile organic compound) reduction devices using sensor modules and to monitor/control long distances using Edge IoT

- Environmental Device Safety Management Technology Using Edge IoT

- High-concentration VOCs detection technology using sensor modularization technology

- Intelligent carbon emission management and predictive control technology

- Operation Technology of Flame-Free Hybrid Oxidator

- Digital Twin Platform Requirements Data Transfer

CO2 direct utilization technology by Co-electrolysis system

This is a technology that directly utilizes captured CO₂ to produce CO and H₂-based syngas through co-electrolysis of CO₂ and H₂O, using electricity generated from renewable energy sources or surplus power

- Design of Co-electrolysis System

- Optimization of Heat Exchange Network

- Operation and Management of Co-electrolysis Stack

- Conversion and Reforming of Syngas for Downstream Applications