Research Fields

Institute for Advanced Engineering

연구부서

- Research Fields

- HOME

Research Fields

INSTITUTE FOR ADVANCED ENGINEERING

Green energy core field original technology

This is a field that develops key core technologies for the entire cycle from the development stage to the operation stage of the power generation system of major green energy sources such as wind, solar, and hydrogen.

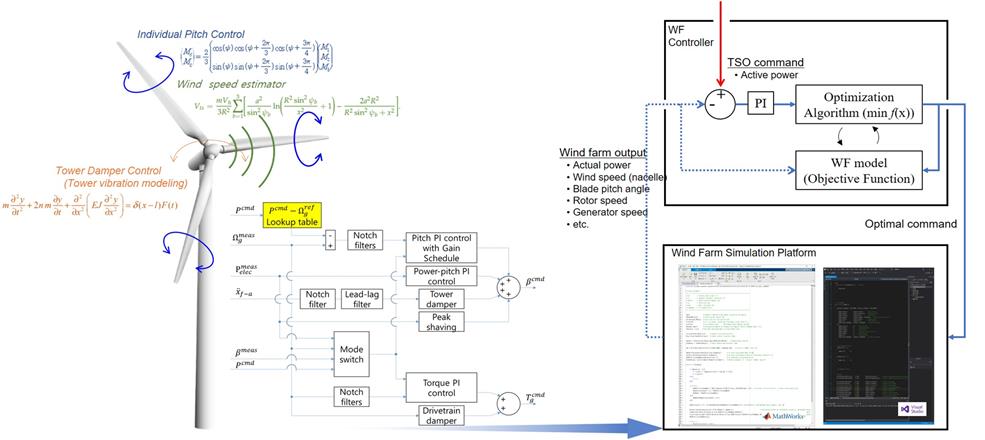

· Wind turbine control algorithm design and load analysis technology

· Micro-siting, wake analysis and wind farm O&M optimization technology

· Liquefied air energy storage/generation technology, establishment of a test base for cryogenic fluid core equipment, and large-capacity ESS technology

· Equipment reliability evaluation/analysis and eco-friendly facility disaster prevention technology

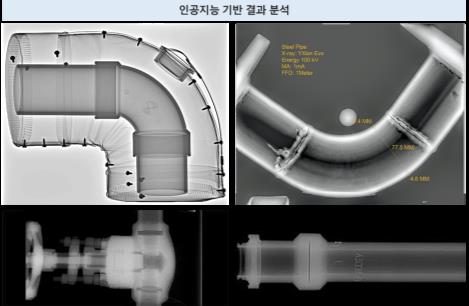

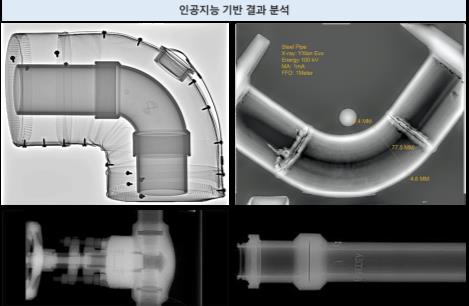

Development of AI-Based Intelligent Interpretation Solution for Radiographic Weld Inspection

· Automated Labeling for Weld Defects

· Augmentation Techniques for Weld Defect Data

· Weld Defect Detection & Segmentation

· Automated Reporting of Weld Inspection Results

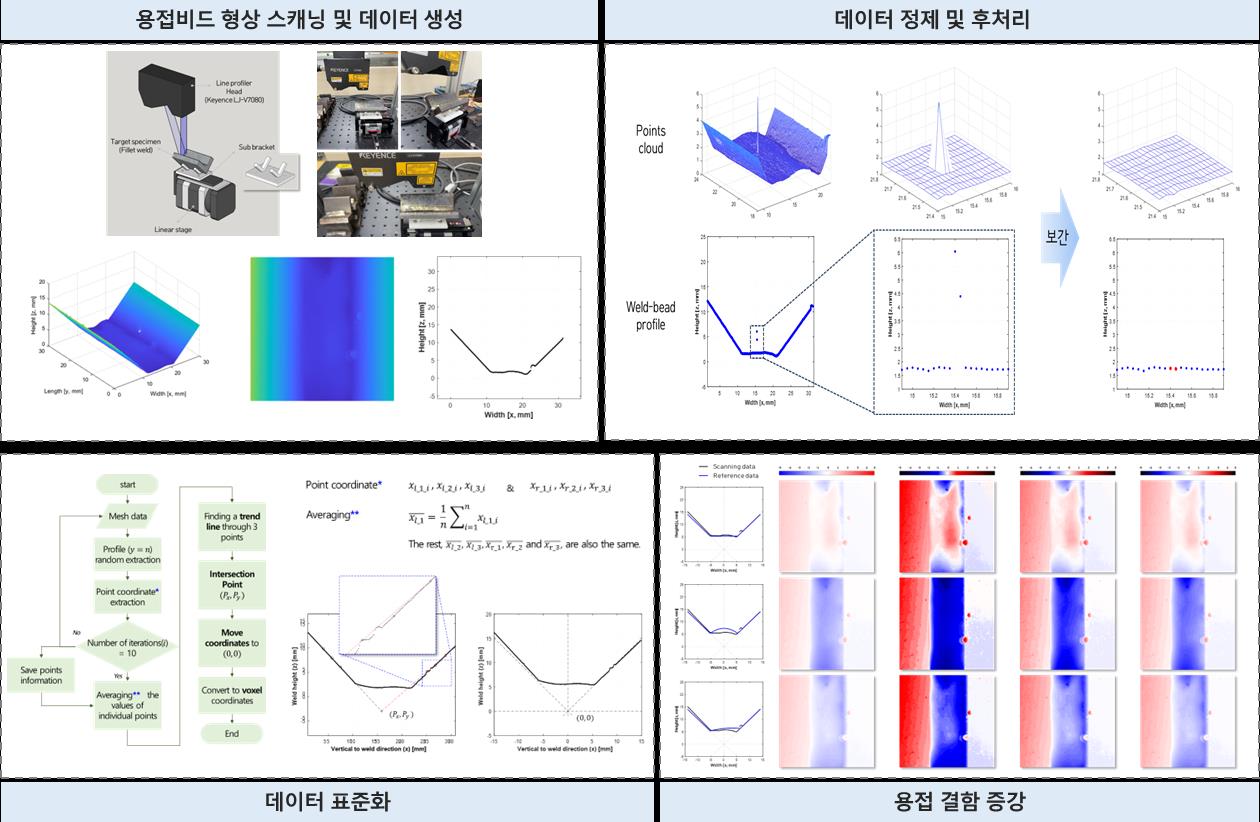

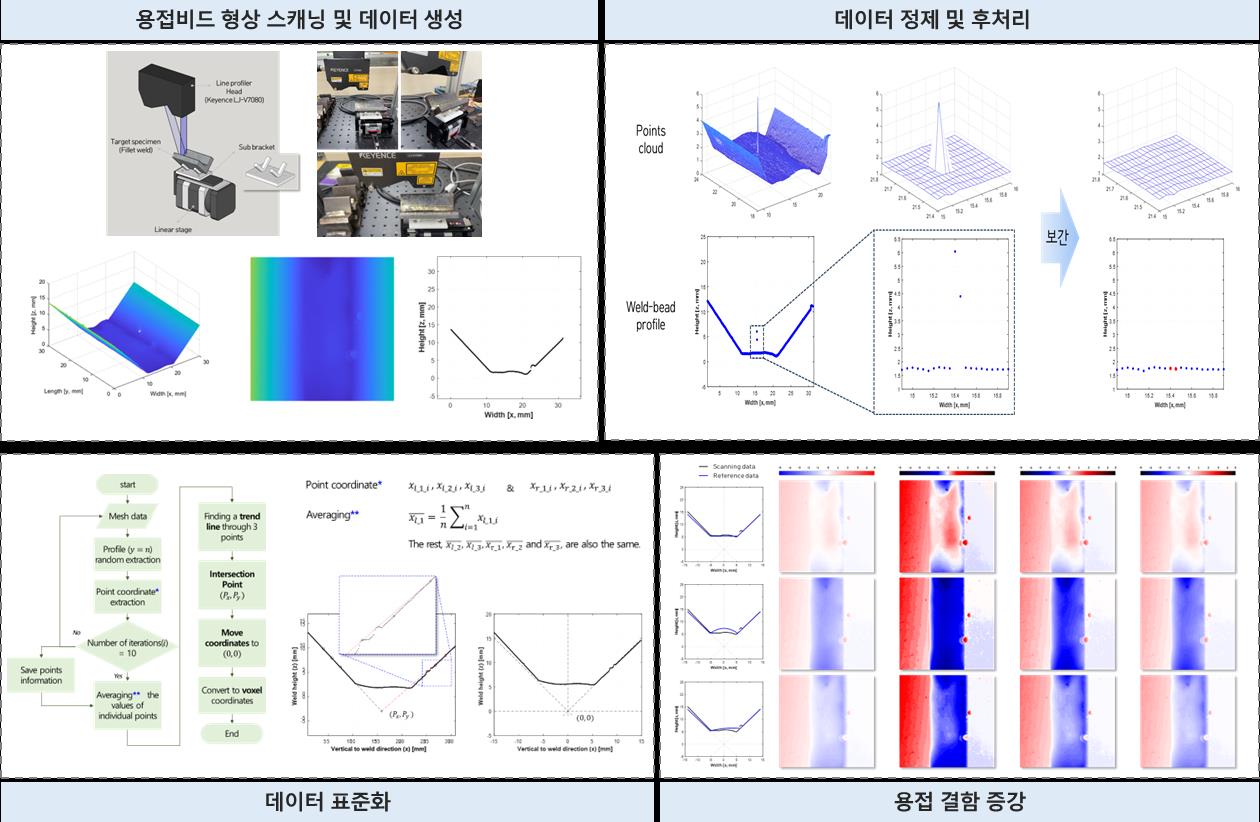

Development of Weld Bead Shape Analysis and Bonding Quality Inspection Solution

· Weld Bead Shape Scanning and 3D Points Cloud Generation

· 3D Points Cloud Data Cleaning and Post-Processing

· Standardization of 3D Points Cloud Data

· Weld Bonding Enhancement Technology

· Automated Weld Bead Defect Detection Technology

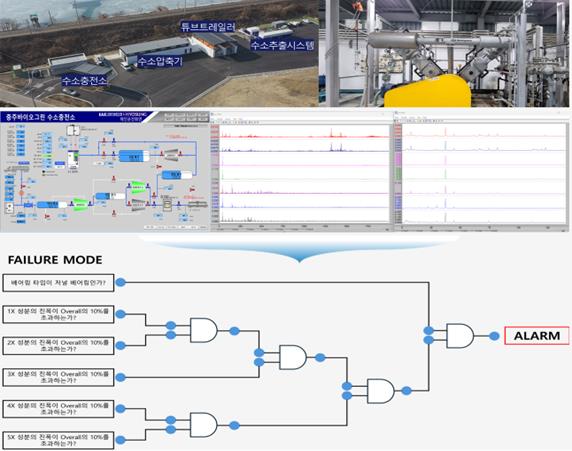

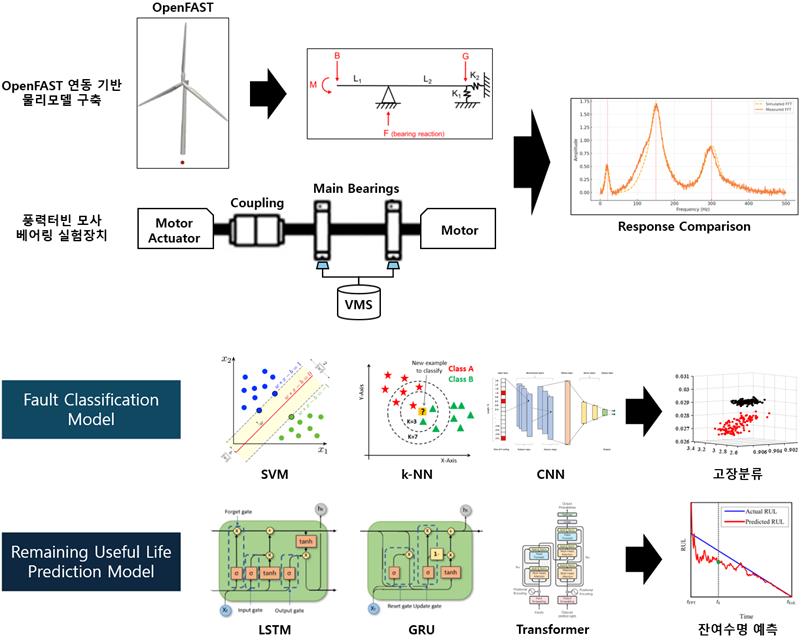

Development of Vibration-Based Condition Monitoring Solutions for Industrial Rotating Machinery

· Advanced Algorithm Development for Condition Monitoring

· Failure Modes and Effects Analysis (FMEA) Technology

· Remaining Useful Lifetime (RUL) Prediction Technology

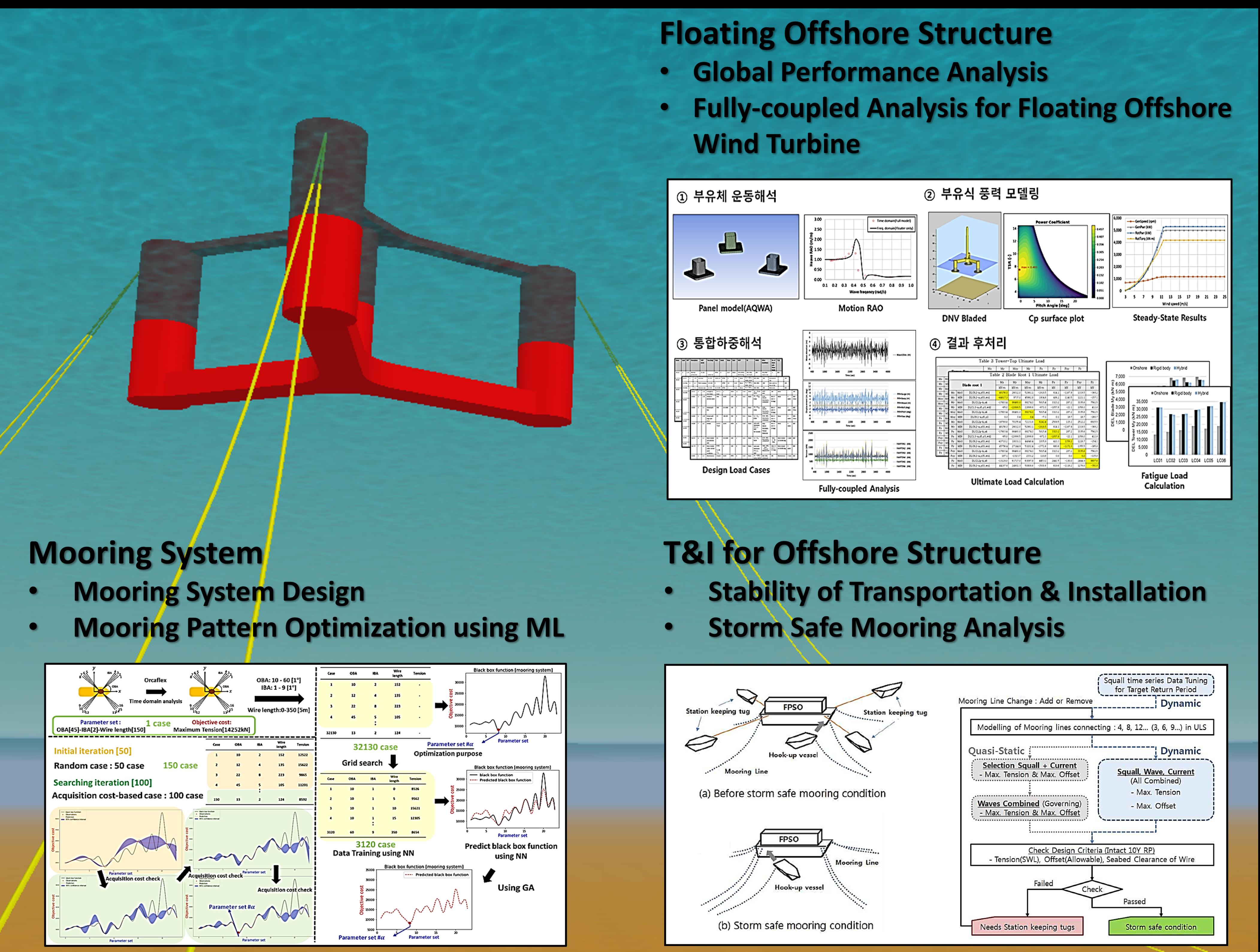

Floating offshore structures/green energy convergence technology

As the location of the complex moves from land to sea in accordance with the trend of enlargement and large-scale green energy systems, a field that develops next-generation energy generation technology by fusing mooring system design technology and integrated coupling analysis technology for offshore structures with existing fundamental technology.

· Evaluation of floating marine structure movement characteristics and mooring system analysis technology

· Floating offshore wind power system integrated coupling analysis technology

· Optimal design of floating marine structure mooring system and artificial intelligence application technology

· Tidal, current, and wave power generation marine renewable energy structure development technology

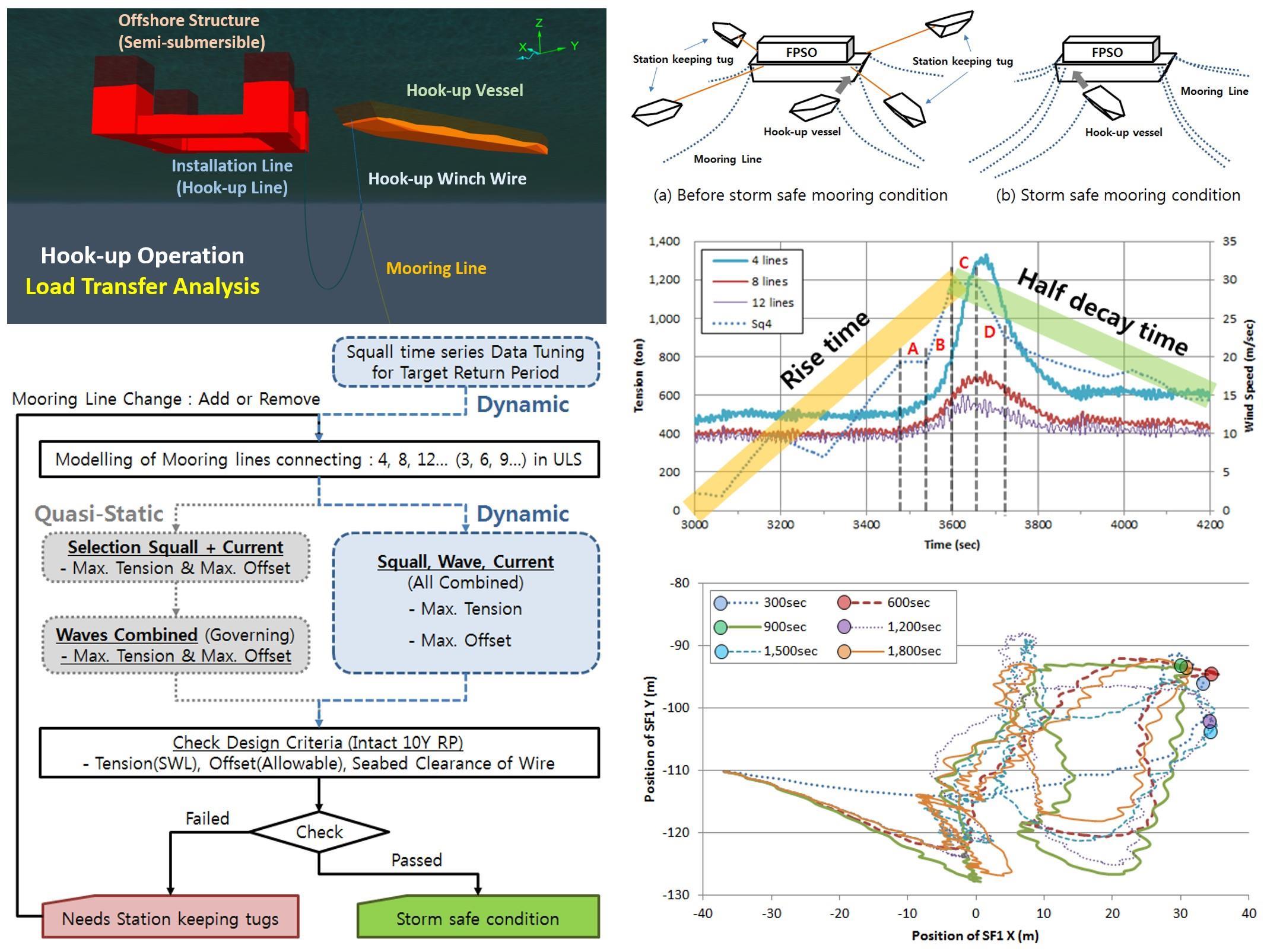

Marine fisheries/disaster prevention structures, marine transportation system development, and marine construction technology

Development of disaster prevention structures to increase marine fisheries resources and protect the coast from the marine environment, development of transportation installation technology for safe and effective marine construction, application of various new technologies and new concepts to ships (or other transportation systems) and marine construction underwater robots (subsea equipment). It is a technology that is developed and applied.

· Technology to develop marine fishery augmentation structures, eco-friendly and marine disaster prevention structures

· Offshore structure transportation & installation (T&I) analysis and stability evaluation technology

· Marine construction/transportation vessel (system) and underwater robot conceptual design, core equipment development and application technology

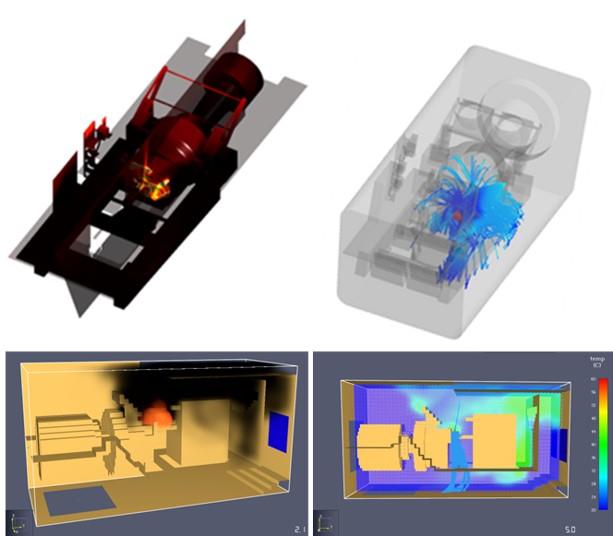

Advanced fire protection technologies

Advanced fire protection technologies are applied to eco-friendly power generation facilities, focusing on safety, risk mitigation, and system resilience. Key capabilities include ignition source risk assessment, FDS–Pathfinder-based evacuation modeling, and CFD-driven design of suppression and cooling systems. Simulation-based optimization enhances the performance and reliability of fire response infrastructure and thermal management systems.

- Fire Protection Technologies for Eco-Friendly Power Generation Facilities

- Comprehensive Risk Assessment for the Identification of Principal Ignition Sources

- Evacuation Route Planning Based on Integrated FDS–Pathfinder Simulation

- Advanced Coupled Fire and Egress Modeling for Safety-Critical Infrastructure

- CFD-Based Design of Fire Suppression Systems and Optimization of Protective Facility Layouts

- Simulation-Driven Engineering for Efficient Fire Response and Spatial Planning

- Cooling System Engineering for Power Generation Equipment

- Design Technologies for Enhanced Thermal Management and Operational Safety

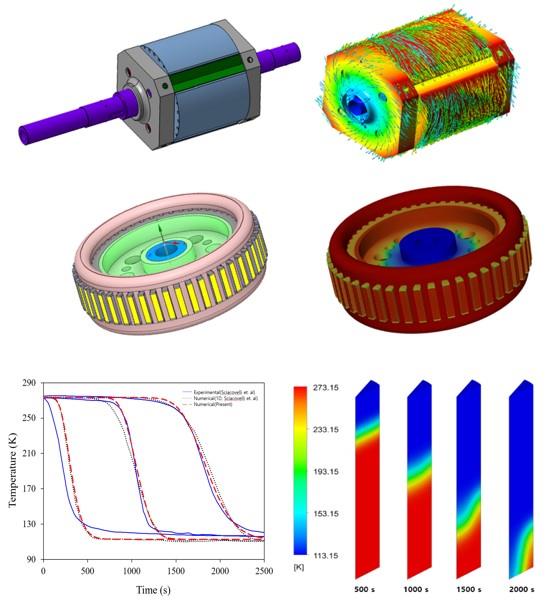

CFD and numerical simulation technologies

CFD and numerical simulation technologies are utilized for the optimal design and analysis of fluid machinery and complex thermal-fluid systems. Applications include cryogenic phase change, wave-body interaction, multiphase flows, and fluid impact load assessment in extreme environments. Reactor thermal output is analyzed with precision, incorporating uncertainty quantification for enhanced safety and operational reliability.

- CFD-Based Optimal Design of Fluid Machinery

: Computational Fluid Dynamics Applications for Performance Optimization - Thermal Energy Storage and Cryogenic Phase Change Analysis

: Advanced Simulation of Heat Storage Systems and Phase Transitions in Cryogenic Fluids - Wave Modeling and Floating Body Analysis

: Numerical Evaluation of Ocean Waves and Offshore Structure Dynamics - Multiphase Flow and Fluid Impact Load Analysis

: Simulation of Complex Fluid Interactions and Hydrodynamic Shock Loads - Reactor Thermal Power Analysis and Uncertainty Quantification

: Accurate Estimation of Reactor Heat Output with Statistical Uncertainty Assessment

Durability performance evaluation technologies for large-scale bearings

Durability performance evaluation technologies for large-scale bearings are applied to yaw and pitch bearings in wind turbines. Test designs address both extreme and fatigue loading conditions to ensure mechanical reliability under realistic operating environments. Component-level durability and service life are verified through rigorous experimental validation and structural assessment.

- Full-Scale Durability Validation Technology for Large Bearings

- Durability Testing of Yaw and Pitch Bearings for Wind Turbines

- Test Design and Evaluation under Extreme and Fatigue Loading Conditions

- Durability and Service Life Assessment of Component parts

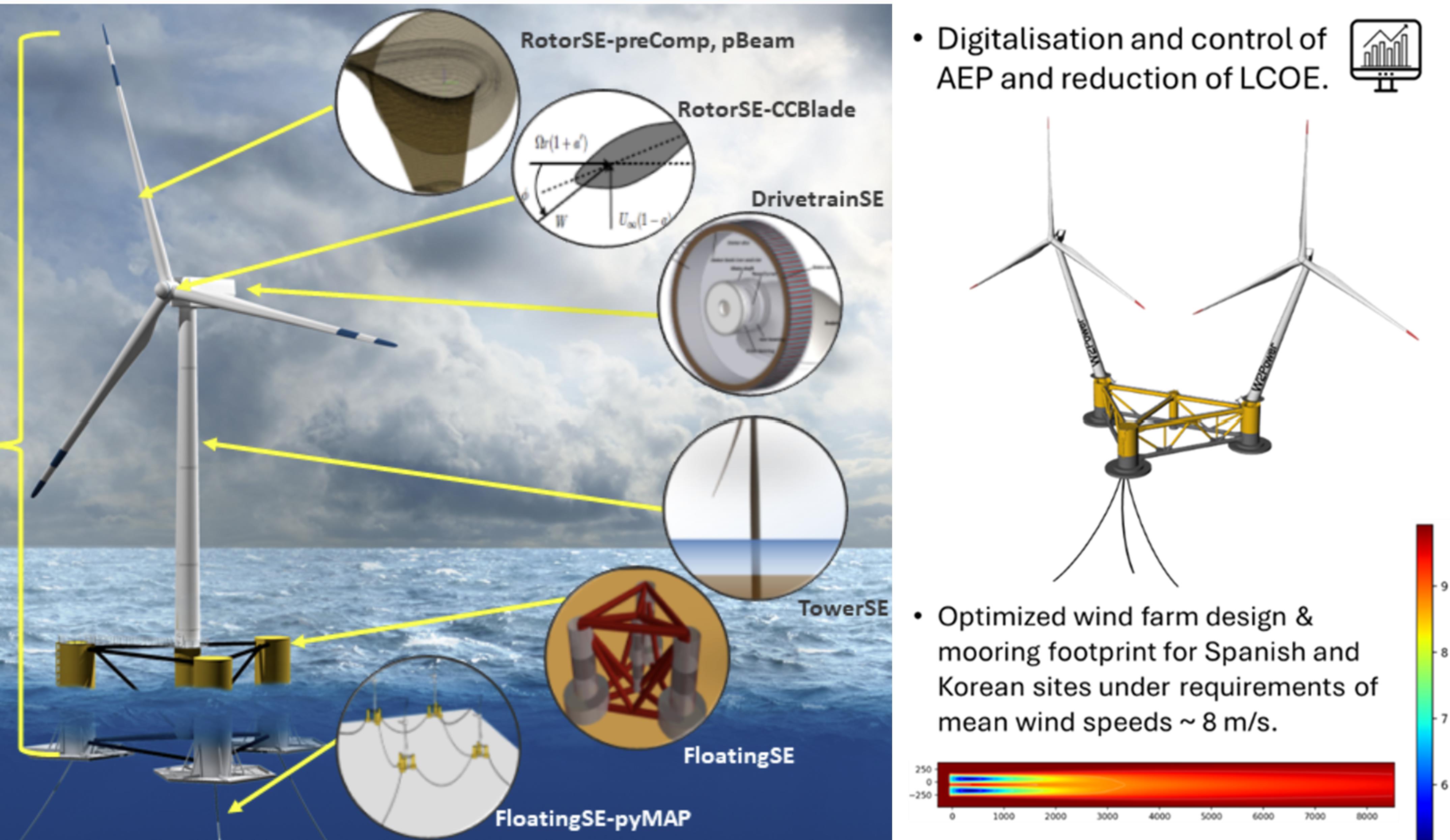

Wind turbine system design and analysis

Design and analysis of conventional (on/offshore) and next-generation wind turbine systems

- Wind turbine system design and optimization based on the OpenMDAO framework

- Dynamic behavior and performance analysis of wind turbine systems using multibody dynamics

- Innovative design methodologies for next-generation wind turbine systems

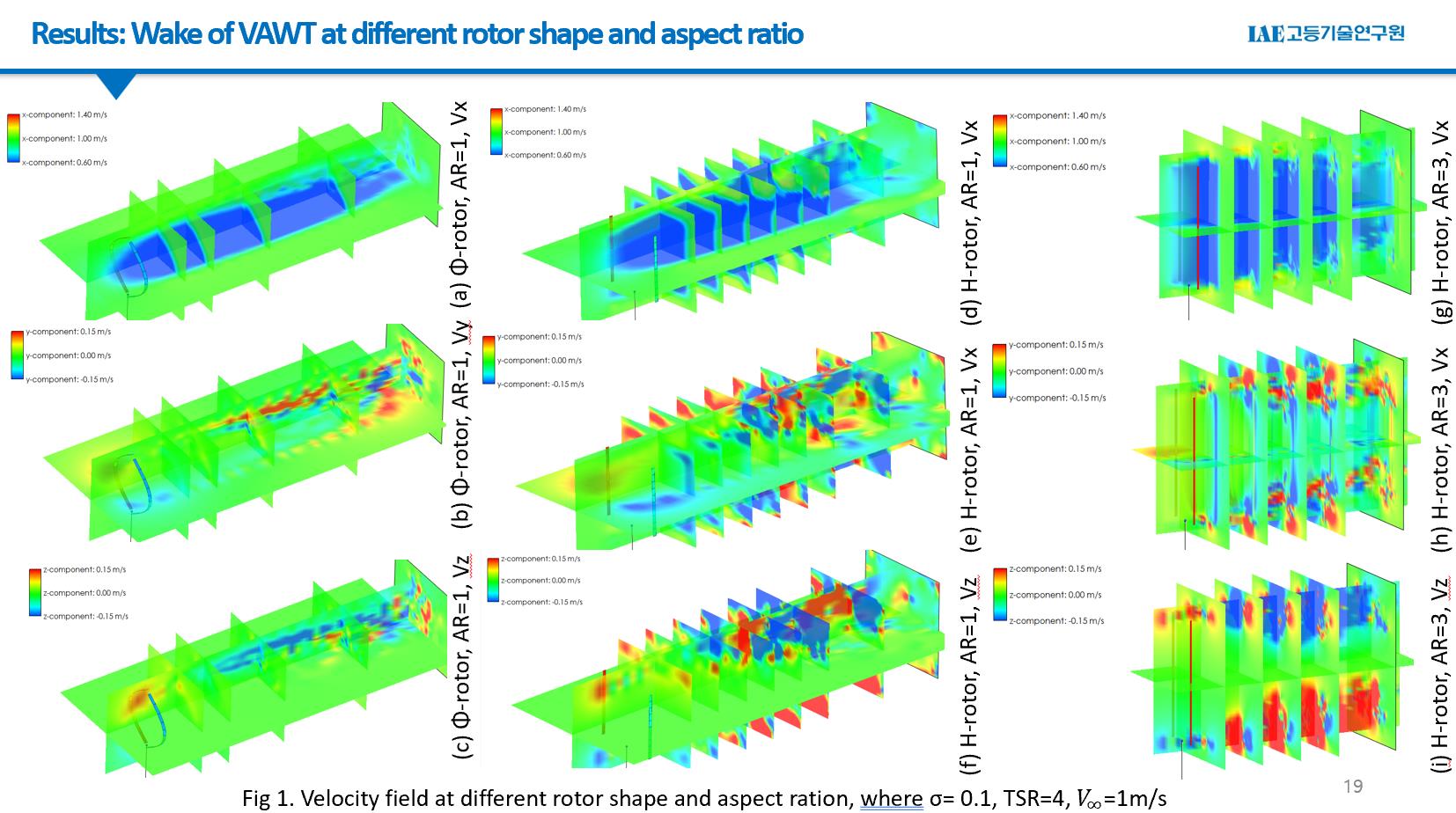

Rotor aerodynamic design and rotor/wake aerodynamic analysis

- In-house BEM and vortex model-based rotor aerodynamic design and analysis

- Rotor and wake analysis based on vortex and CFD approaches

- Innovative rotor design and rotor/wake analysis technologies for novel wind turbine concepts

Development of AI-Based Intelligent Interpretation Solution for Radiographic Weld Inspection

- Automated Labeling for Weld Defects

Development of AI-assisted auto-labeling techniques to generate accurate annotations for various types of weld defects in radiographic images, reducing manual labeling effort and enhancing dataset quality. - Augmentation Techniques for Weld Defect Data

Implementation of advanced data augmentation methods to increase the diversity and robustness of training datasets, improving model generalization to real-world conditions. - Weld Defect Detection & Segmentation

Application of deep learning algorithms (e.g., CNN, U-Net) for precise detection and segmentation of weld defect regions, enabling reliable identification of flaw types and sizes. - Automated Reporting of Weld Inspection Results

Generation of standardized inspection reports with visual overlays and classification results, supporting decision-making and quality assurance in industrial settings.

Development of Weld Bead Shape Analysis and Bonding Quality Inspection Solution

This project aims to develop an intelligent inspection solution that utilizes high-resolution 3D scanning data to quantitatively analyze weld bead profiles and automatically detect bonding defects. The solution is composed of the following core technologies:

- Weld Bead Shape Scanning and 3D Points Cloud Generation

High-precision line laser scanning technology for accurate acquisition of 3D weld bead geometry data - 3D Points Cloud Data Cleaning and Post-Processing

Noise filtering, outlier correction, and profile interpolation techniques to enhance data quality - Standardization of 3D Points Cloud Data

Coordinate transformation, alignment, and voxel conversion to prepare data for efficient analysis - Weld Bonding Enhancement Technology

Comparative analysis with reference profiles to visualize defect locations and improve bonding quality - Automated Weld Bead Defect Detection Technology

Deep learning-based methods for automatic detection and classification of weld defects

Development of Vibration-Based Condition Monitoring Solution for Industrial Rotating Equipment

An integrated solution supporting optimized preventive maintenance decision-making through real-time equipment anomaly diagnosis via vibration signal analysis, FMEA-based failure risk assessment, and remaining useful lifetime prediction based on multi-sensor data.

- Vibration Signal-Based Equipment Condition Diagnosis Algorithm Development Technology

Advanced algorithm development technology that diagnoses equipment abnormalities in real-time through vibration data analysis reflecting the dynamic behavior and defect characteristics of rotating machinery. - Failure Risk Analysis (FMEA) Technology

Technology for establishing failure risk assessment and preventive maintenance strategies based on systematic and quantitative FMEA (Failure Modes and Effects Analysis) through analysis of failure modes and effects for key components. - Remaining Useful Lifetime (RUL) Prediction Technology

Technology supporting real-time equipment health assessment and optimal maintenance decision-making through the development of a remaining useful lifetime (RUL) prediction model based on machine learning and signal processing utilizing multi-sensor data.

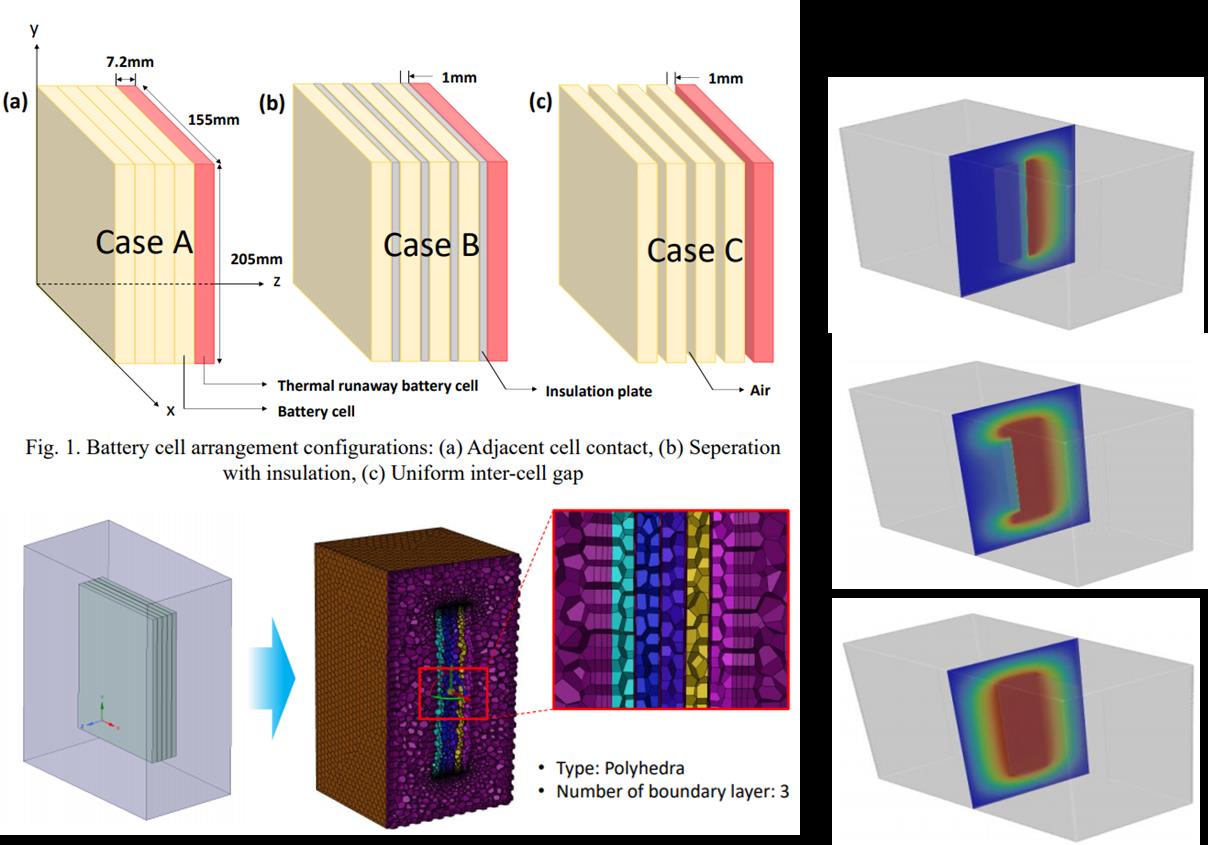

Thermal Runaway Prevention and Suppression for Lithium-ion Batteries

Research focuses on early detection, isolation, and suppression of thermal runaway in lithium-ion batteries. Propagation mechanisms are analyzed through simulation and experiments, with comparative evaluation of suppression agents. Thermal barriers, venting paths, and compartmentalization are designed to prevent fire spread from cascading failures.

- Fire Risk Assessment Across the Entire Lifecycle of Secondary Batteries

- Design Technologies for Battery Suppression Agents and Fire Protection Systems

- Thermal Propagation Simulation at Cell, Module, and Pack Levels

- Off-Gas Venting and Flame Spread Analysis

- Protective Compartmentalization and Isolation Technologies

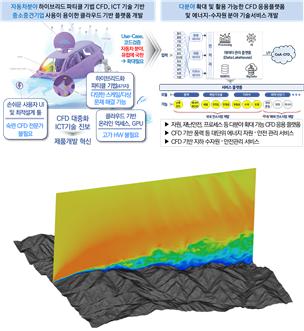

Particle-Based Cloud CFD Application Technologies for Wind Farm Analysis with Enhanced Usability

Development of particle-based cloud CFD application technology optimized for usability and cost-effectiveness

- Development of turbulence analysis techniques for wind farms

- Development of scour analysis technologies around subsea structures such as fixed-bottom wind turbine foundations

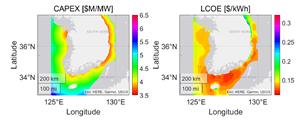

Development of Digital Offshore Wind Resource Maps and Economic Feasibility Maps for Floating Offshore Wind

Construction of digital offshore wind site maps with integrated economic feasibility analysis to support planned site development

- Full lifecycle cost analysis, including installation and O&M (operation and maintenance)

- Validation and refinement of cost analysis methodologies through optimized wind farm design in key regions of Korea